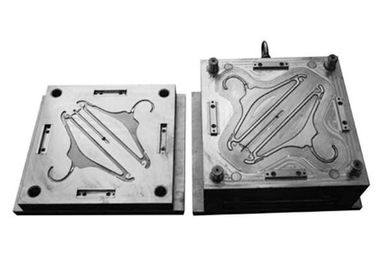

Professional Plastic Injection Mould Custom High Precision For Clothes Stand

Vehicle Mould, plastic Injection Mold

Home Appliance,Industrial,Automotive,various Range

Plastic Injection Mould,Plastic Injection Molding

Quick details:

Shaping Mode: customized plastic parts tooling

Mold material: NAK80, S136, 718H, 718, 45#, 50#, P20, H13, 718 & 2738..etc.

Moldbase standard: FUTABA, LKM, HASCO, DME

Cavity: single or Multi cavities

Gate type: sub gate, site gate, pin-point gate, edge gate...etc.

Mould runner: hot & cold runner

Mold lifespans: rapid tooling small batch for 10K~20k shots, production mould can up to 1000k shots

Texture: MT texture, polishing, clear, color..etc you can choose.

Plastic Material: ABS, PP, PC, PA, PMMA, PS, POM, PBT, ASA., etc.

Product Description

| Product name |

online shopping china supplier injection molding tooling |

| Mould material |

NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, 40Cr, 60#, 45# etc |

| Mould base |

45#,50#, LKM, HASCO etc. |

| Mould cavity |

Single or multi |

| Sprue gate |

Hot runner, Cold runner, Pin-point gate, Submarine gate, etc |

| Design software |

UG, PROE, CAD, CAXA, Solidwork ect. |

| Plastic material |

PP, PC, PS, PE, PU, PVC, ABS, PMMA, ect. |

| Main process |

Milling, grinding, CNC, EDM, wire-electrode cutting, carved, electrospark, lathe, etc |

| Surface treatment |

Words corrosion, mirror polish ,frosted surface or textured surface |

| Mould testing |

On your suggest machine |

| Packaging |

Wooden Cases |

| Mould life |

300,000-3,000,000 shots |

| Delivery time |

45-90 days |

| Payment Terms |

T/T or L/C or Moneygram or Palpay |

| Transportation |

By Sea or by air |

| Export Country |

Worldwide |

| Specification |

Depends on customer's requirements. |

| OEM order |

Welcome |

Our Services

Injection mould, die casting mould, metal and plastic prototyping, sheet stamped parts, insert/over molds,multi-cavities mould, rubber injection mould,etc.

Product range: high quality electronic product, automotive components, medical device, home appliance, etc.

Advantages:

1. Mold design is subject to customer's requirement.

2. Injection molding machine specification of certain plastic,etc.Our products include a variety of vacuum cleaners,and plastic components.These products are widely available to world-class large companies.We have won a high reputation among clients.Our company provides processing or researching and manufacturing services.We are very interested in the development of new products to meet market demands.

3. specifications about flow,material,radian and so on,we can fit in all you want.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!